transaxle

07

Jan

Body, engine and radiator fitment.

- By basil

- No Comments

Great updates today! Kevin did a preliminary mock fitting of the body on the chassis with the radiator and motor. It’s starting to look like a real car.

- First fitting of the engine, chassis and radiator.

- EZ30R and radiator fitment in low light Karmann Ghia.

- Exhaust – first round mockups.

- A little closer view of where the motor sits.

30

Dec

Engine, transaxle and radiator mounted!

- By basil

- No Comments

- Engine, transaxle and radiator – closeup.

- Side view of the mounted engine and radiator placement.

- Rear view of the mounted engine

It’s starting to look serious!! Exhaust build/fitment work up next.

21

Nov

Transaxle with body on.

- By basil

- No Comments

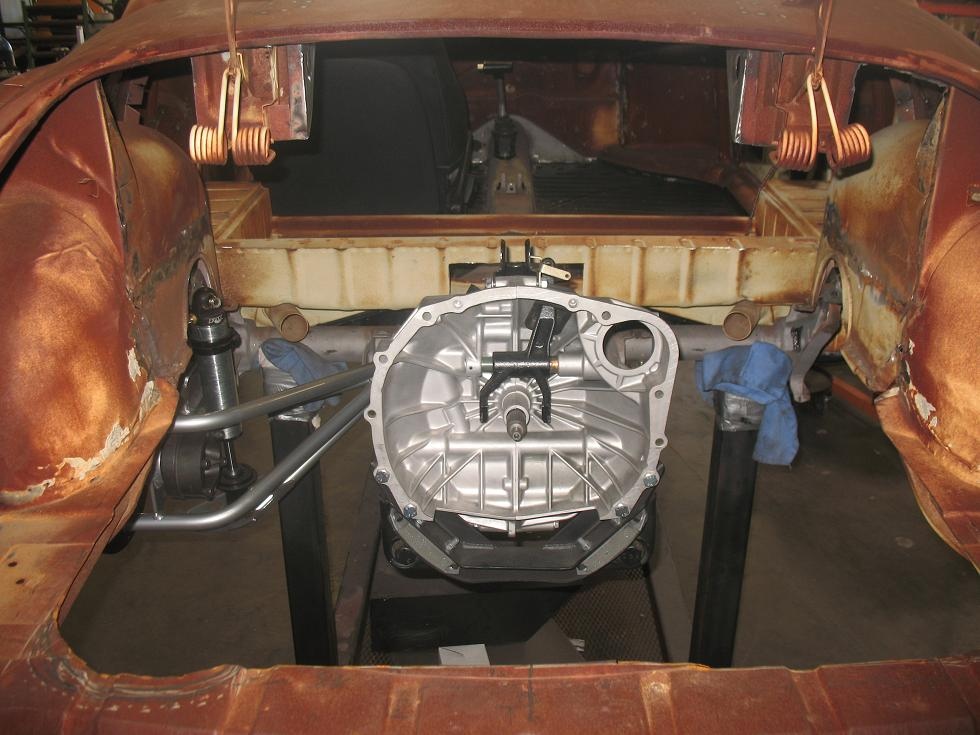

Today we have before and after pictures of where the transaxle fits.

This first picture is of the 1958 body, chassis and stock transaxle:

This second picture is with the 1958 body on the new Mendeola chassis and Subaru transaxle:

And finally, close ups of the new setup:

08

Oct

Transaxle fitted in chassis.

- By basil

- 2 Comments

The SubaruGears transaxle mounted and shifting! Kevin is an artist!

22

Sep

Transaxle built!

- By basil

- No Comments

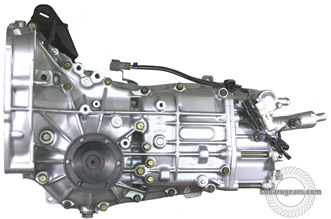

SubaruGears has shipped the transaxle. Should clear customs and arrive stateside in about a week.

Some pics of the transaxle build:

20

Sep

Build update..

- By basil

- 4 Comments

Lots of updates today:

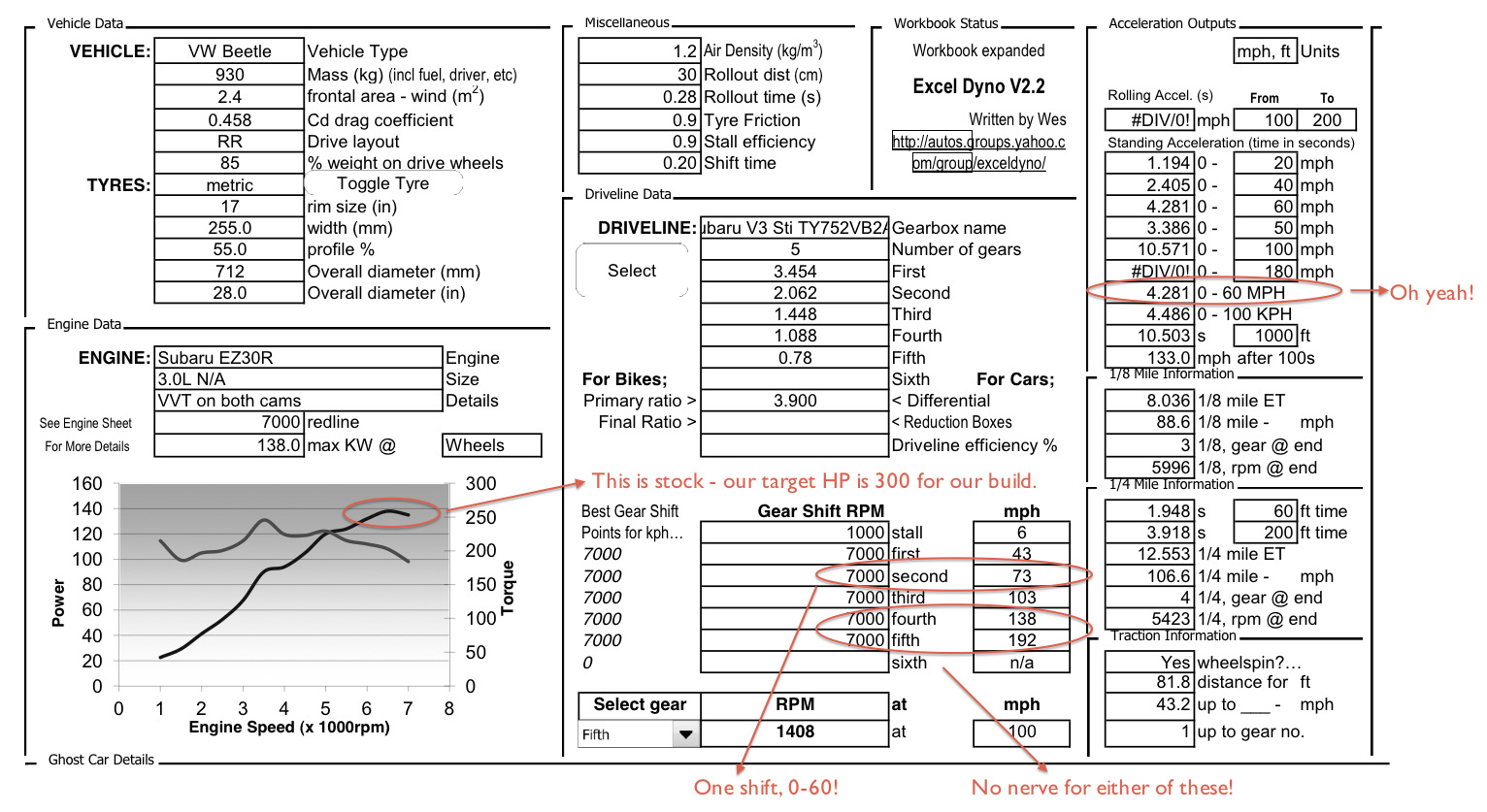

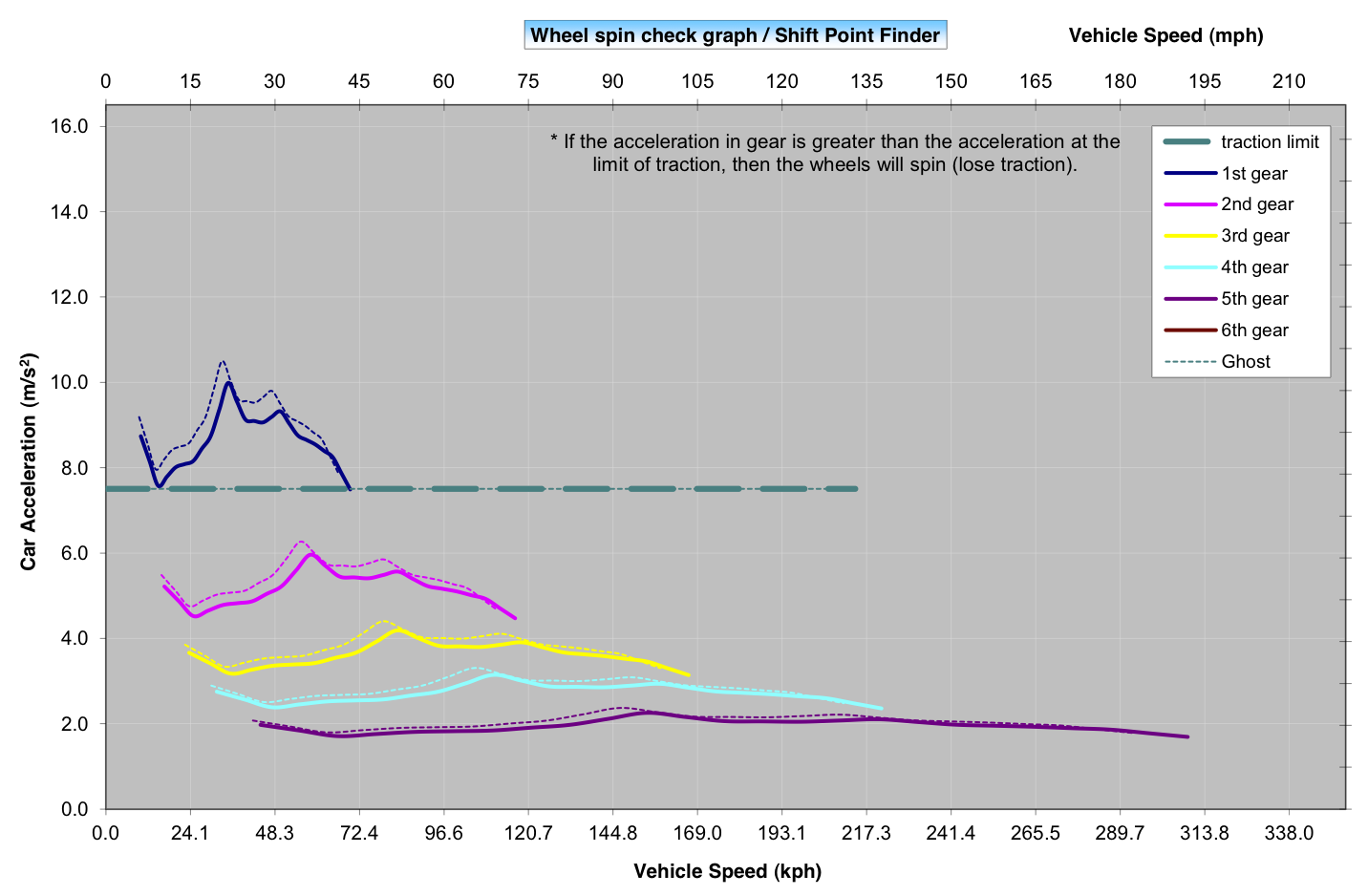

- Motor.John at Outfront Motorsports is working on the motor. He performed a preliminary cylinder leak down test on all cylinders and the motor came in at 2%! A leak down test measures the amount of air needed maintain pressure within a static cylinder. Good readings come in around 5-8%. Seems like this engine hasn’t reached its break-in period. This is all very, very good news. John and I decided to go with the new AEM ECU (which supports the Subaru AVCS) but it’s still in beta and he will be prepping the motor to run with an existing harness setup. We’re not doing any cosmetics at this time.

- Brakes. The race disc brake kit has been ordered from Airkewld. Pete tells me that they should ship in about a week and half. 4-piston wilwood calipers up front and 2-pistons in the rear. The rotor bolt pattern is 5 x 114.3 (see wheels below). The only problem I foresee with these is that they don’t have a mechanism for the e-brake setup. The e-brake will be required for state inspections here in Virginia.

- Transaxle. SubaruGears said that the transaxle should be complete by Monday and he’ll ship sometime next week, so we should have it in 2.5 weeks at the latest.

- Wheels. I have found two wheel types that I like. Both are 17×7 with with 5×114.3 bolt pattern. Finding 17″x7, 5×130 wheels that I liked was nearly impossible (everything that I loved was only 18×8.5) so based on Airkewld’s advice they will ship the rotors with the more popular 5×114.3 pattern. I remember the old school Momo five spokes back in the day.

Now – which do you like better? Some quick and dirty mockups with Photoshop:

Recent Comments