cooling

01

Sep

Toe and Flow

- By basil

- No Comments

Mendeola True Track toe adjustment guide.

Finally had some free weekend time to seriously work on the cooling and rear suspension. Updates below, enjoy.

Toe

After straightening out the rear end’s body work. It was obvious that the rear toe was too aggressive. It was pretty much aligned to a body that was mis-aligned. :). On the Mendeola site it recommends between 1/4 and 1/8 inch toe but I think Revenant team measured it to be 1.5 inches in total. Mendeola’s True Track rear end makes toe adjustment pretty straightforward. CJ made the adjustments and we took the car out for a spin in the dusk of the early evening.

With CJ holding a big spot light for visibility, we drove the car over to our buddy Veek’s house. Veek built a rat rot model A Ford and I made sure he heard us coming up his driveway but of course he wasn’t home! ;)

Flow

Fans weren’t working at first so we powered them up outside of the ECU relay for confirmation. They worked, but were turning the wrong direction! We tracked down the wires coming off the fans and reversed the polarity to have them push instead of pull which was against the expected air flow design. Problem one solved.

After pulling the cover of the high voltage ECU relay panel, there was one disconnected wire (ECU-) so we hooked that up and did a better job of seating/connecting the fan wire to the GPO4 terminal. (We will be going through and fixing the wiring properly after we pull the body).

We fired up the car, laptop/ECU software and manually triggered the fan and boom, it all worked out. We will tune this a bit later but we are in a good spot here. We turned on data logging and let the thermostat open up. At idle, the car held around 95C which is the standard operating temperature for our EZ30R engine.

So for the benefit of those new to this build and my Ghia enthusiasts, yes that rear grill looks pretty strange with the air vents relocated to the rear as shown. We did some software based testing of the airflow and we think that the vents place here are the best place to take advantage of the low air pressure. This is what we are testing.

We added some yarn to the deck lid to record video of the air flow based on the relocated deck lid vents. We quickly realized that we’ll need a manometer to really check the pressure differential so will be ordering one of those soon.

We were going to do the video recording the next day but ran into to some seriously bad news. CJ spotted a unfamiliar vehicle in the woods where we ride dirt bikes and after a quick investigation discovered that some gentlemen had committed suicide in the vehicle. He had been dead for 2-3 days. 911 was called and after the parade of emergency vehicles showed up, our little stretch of country back road testing ground was done for that day.

I wish I could have talked to that guy before this incident – very sad indeed and it took a bit of time to process a discovery like this. Sorry to end on a sad note. If you know of anyone dealing with depression, hard times, life in general, etc please get them help. Suicide hotline resources.

06

May

Aerodynamic exploration

- By basil

- No Comments

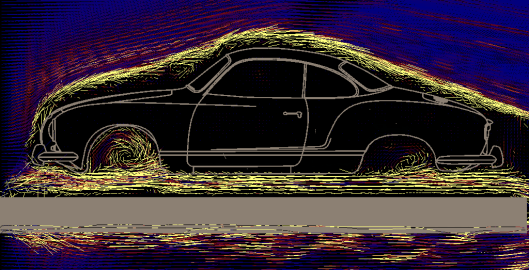

Tinkering with a wind tunnel simulator on the iPad. The low light is extremely slippery in the wind. Check out the laminar flow.

25

Feb

Chassis assembly – coming together..

- By basil

- No Comments

Good updates received today. The Redline ECU was delivered. All parts have returned from powder coating and Kevin has installed the radiator frame and coolant pipes. The motor was re-bolted to the transaxle as well. The car is really, really coming together although we still have a long ways to go.

Next up – kafer bars, completion of the starter system, ECU installation, fuel system and finding some cheap tires.

- frontal view of the chassis, with brakes, radiator setup and black mamba shifter.

- Powder coated coolant pipes.

- Redline ECU (to be installed soon).

- Three cooling fans.

18

Jan

Cooling system, plumbing completed..

- By basil

- 2 Comments

Kevin did an awesome job on the plumbing for the cooling system. The system will be disassembled shortly for powder coating.

- Custom plumbing work.

- Cooling system pipes – 1.

- Cooling system pipes – 2.

- Cooling system pipes -left side.

- Cooling system pipes -top view.

- Radiator cold return.

- Cold return closeup.

- Radiator hot entrance.

- Hot side entrance closup.

07

Jan

Body, engine and radiator fitment.

- By basil

- No Comments

Great updates today! Kevin did a preliminary mock fitting of the body on the chassis with the radiator and motor. It’s starting to look like a real car.

- First fitting of the engine, chassis and radiator.

- EZ30R and radiator fitment in low light Karmann Ghia.

- Exhaust – first round mockups.

- A little closer view of where the motor sits.

27

Dec

Rear radiator frame

- By basil

- One Comment

We have some updates on the radiator placement. Seems to be a bit of interest in this. The idea here is to have air flow from under the transaxle, up to the frame shown here, through the radiators and out the rear deck lid. We have a ways to go in terms of the scoops, etc. Not sure if this could be pulled off in a bug?

Check the photos below to see where we’re headed:

- Ghia radiator frame right side.

- Ghia radiator frame front left.

- Ghia radiator frame transaxle view.

- Front close up.

- Side view – no radiator, frame only.

- Ghia radiator frame left side.

21

Nov

Cooling system design

- By basil

- No Comments

While in San Diego, Kevin and I discussed our cooling system options. Most folks doing Subaru conversions are mounting the radiators upfront in the spare tire well. Kevin wanted to do something different and after sketching out the concept on paper, I thought it was pretty cool.

Originally I was thinking that we’d place the radiator upfront just like everyone else, but it’s a tight fit and the air flow may have been problematic. It was explained to me that getting air to the radiator was the first half of the problem. Getting air out was the second half. I had visions of doing a custom reverse funnel type shroud that you find in the front noses of water cooled 911s where an intake shroud funnels air to two of three radiators. I wasn’t sure if lowlight Ghia nostrils would provide the surface area needed which would have led to making a third open or scoop down low near the horn boot opening. Being a lowlight, I didn’t want to mess up the front nose in any way. Plus, I was thinking that we could benefit from the extra weight over the front wheels.

But it was not to be.

Kevin’s idea was to build a rear mounted cooling system just above the transaxle and forward of the motor. The idea is to scoop air up from the bottom of the chassis, direct that to the radiator and then flow it out the back over the motor, similar to a standard air-cooled VW.

To pull this off, the parcel area behind the rear seat would need to be sacrificed temporarily while Kevin worked out the framework for the radiator and air flow. Here’s what the car looks like with that parcel cut out:

Once the radiator and system are fitted, a new firewall will be constructed to isolate the radiator and engine compartment from the interior.

Recent Comments